Wallcoverings industry

For over 70 years we have been setting standards in the wallcoverings industry with our innovative production facilities. This continuous innovation has made us the largest supplier of machines for this particular industry today. In the last twelve years alone, our engineers and process specialists have implemented hundreds of projects - including more than 60 combined printing systems for the pan-European wallcoverings industry.

Machines from OLBRICH offer you maximum productivity and economy as well as an extraordinary variety of application possibilities. You can rely on our personal advice, punctual deliveries and detailed documentation of all relevant parameters.

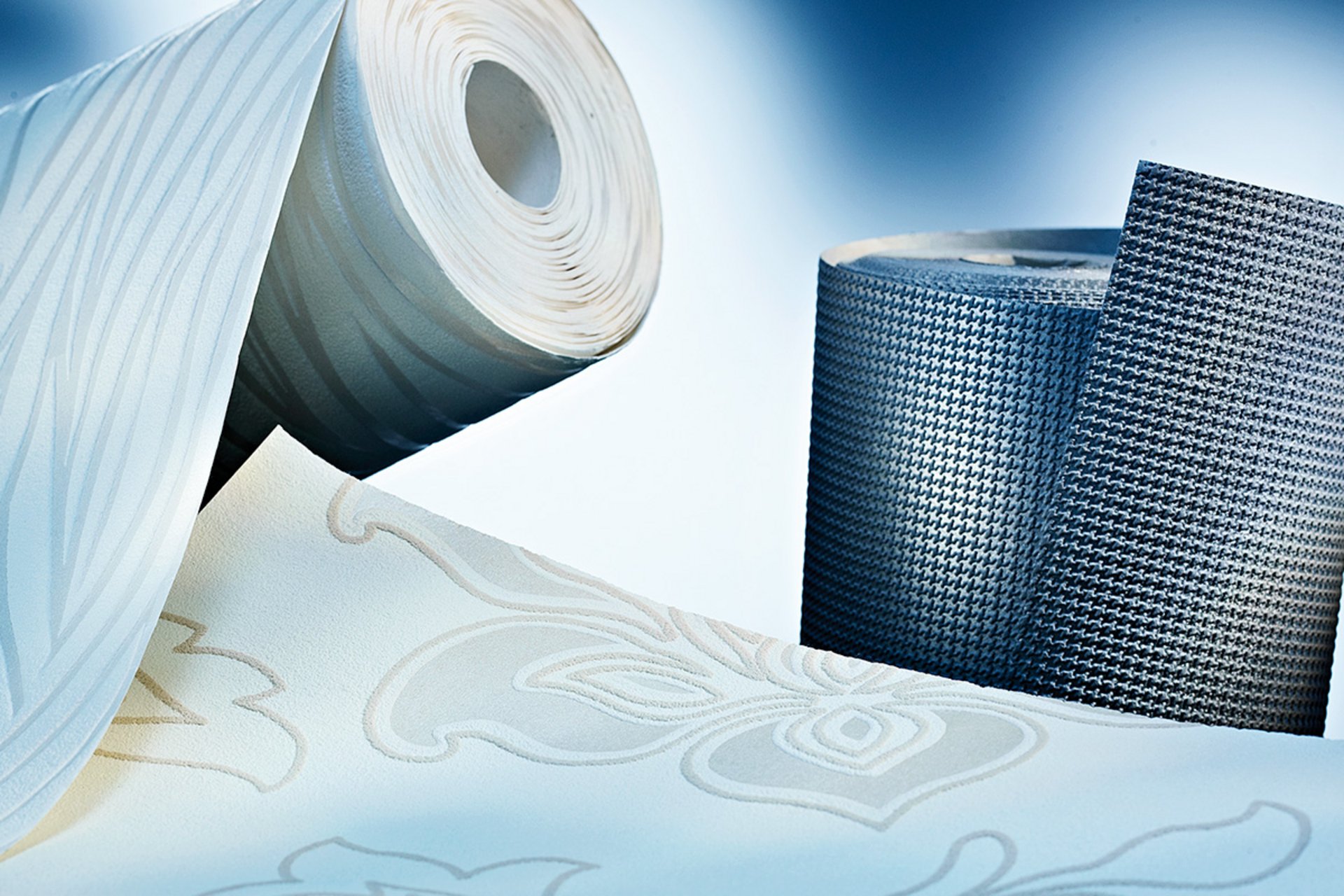

With our systems, you can effortlessly create a variety of different decors using a wide variety of materials. Highest reliability and quick change-overs for minimum downtimes are a matter of course for your OLBRICH systems.

Wallcoverings coating

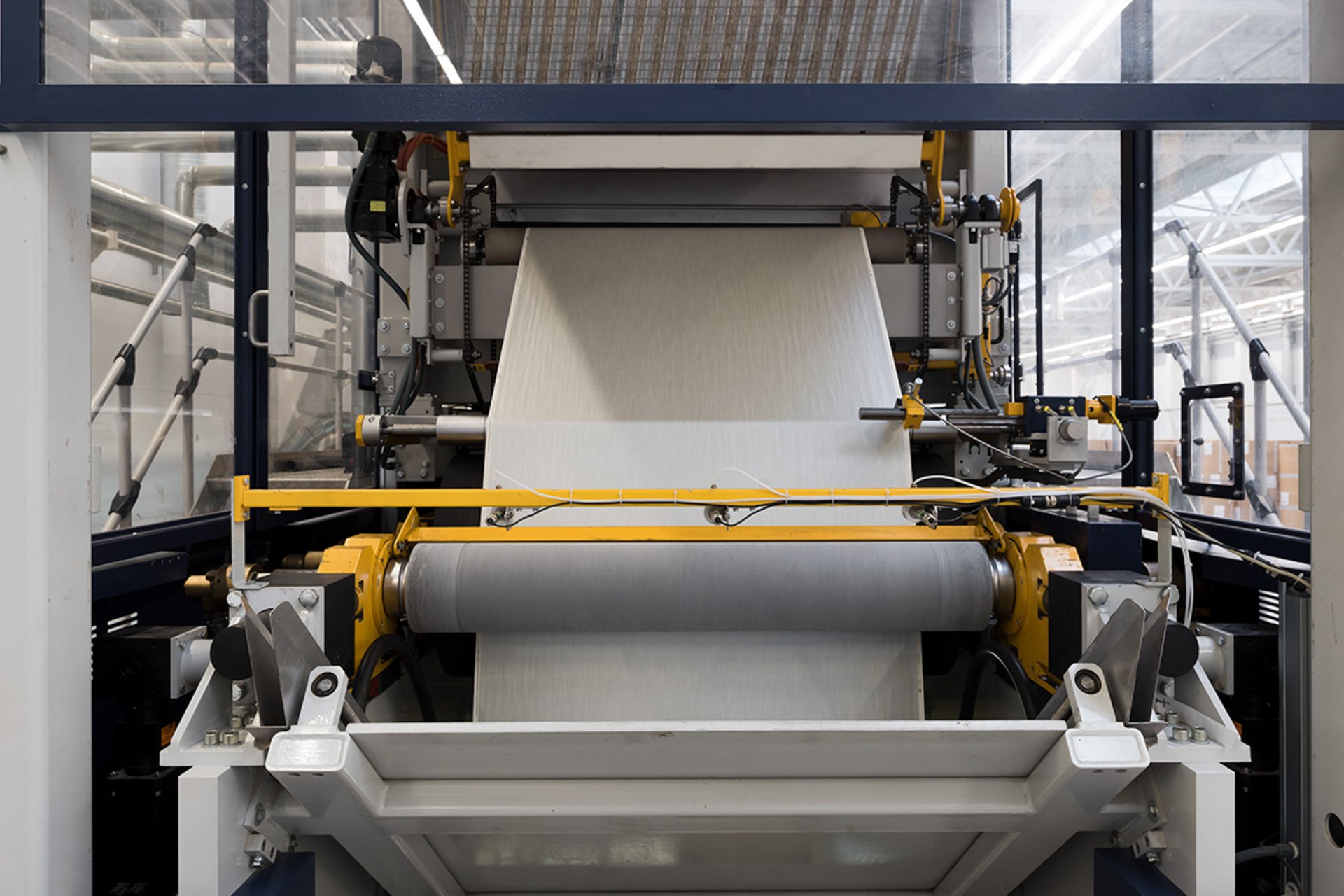

With coating systems from OLBRICH you can rely on maximum precision and maximum reproducibility. The individual components of our machines are accurate to a tenth of a millimetre. At the same time you have the choice between various wallcoverings coating processes and media.

Our systems offer you maximum production reliability and first-class results. For example, you can produce high-quality coatings for duplex and simplex wallcoverings, PVC compact or hot embossed wallcoverings and foam wallcoverings - with paper or non-woven backing as desired.

The working widths of our coating systems are 1,200 millimeters, the production speeds up to 100 meters per minute. The coating weights range from 60 to well over 600 grams per square meter. Due to the special ease of cleaning of our machines, you benefit from a favorable ratio between production and cleaning times.

Your advantage at OLBRICH: Our industrial coating systems are universally scalable, so that you can also produce larger quantities if required.

Exemplary coating technologies:

- Coatings with screen coating heads

- Reverse-Roll-Coater (RRC)

- PVC coating lines

- Integration of printing processes

Wallcoverings printing and varnishing

With OLBRICH machines for printing and varnishing wallcoverings, you achieve maximum efficiency and minimized scrap quantities. At average production speeds of typically 70 to 80 meters per minute, the mechanical speed is twice as high. Various printing technologies are possible. At the same time, you can also produce small batch sizes particularly economically.

With our combined systems for coating, printing and embossing in register, you also benefit from further efficiency and speed advantages - for example in the production of compact and foam wallcoverings.

Exemplary printing and coating technologies:

- Gravure printing units

- Screen printing units

- Flexographic printing units

- combined printing plants

Drying wallcoverings

With our effective machines and plants for the drying of wallcoverings you will achieve optimal results. Temperature stability and constant air velocities have the highest priority for uniform and gentle drying. In the development phase, we use computer simulations as well as trials with dryers in our technical centre for your project.

The working widths of our energy-efficient drying systems are 1,200 millimeters, the production speeds 60 to 80 meters per minute. To ensure the consistent drying quality of your wallcoverings, our systems guarantee maximum temperature accuracy across the entire product width - with the highest repeat accuracy.

Depending on the product, you can choose between upper air systems or a combined upper and lower air system for high performance with large coating weights. Your systems are particularly flexible with independently adjustable recirculation and exhaust air control.

Exemplary drying technologies:

- Top Air Dryer

- Upper and lower air dryers

Laminating and bonding wallcoverings

Laminating and bonding machines are currently only used occasionally in the wallcoverings industry for duplex wallcoverings and for commercial wallcoverings.

Do you have special requirements for laminating and laminating wallcoverings? Our machinery specialists will be pleased to advise you in detail and also implement special solutions for complex tasks.

Embossing and smoothing wallcoverings

Inspire your customers with unique surface structures - with embossing machines from OLBRICH. This opens up completely new possibilities for innovative products. We are happy to integrate embossing and smoothing processes into your existing systems.

With efficient machines from OLBRICH, you can rely on maximum production reliability and first-class results. For example, you can achieve high-quality embossing and smoothing results for duplex/simplex wallcoverings, PVC compact or hot embossed wallcoverings as well as foam wallcoverings - optionally with paper or fleece backing. The repeat accuracy can be as good as +/- 0.25 millimetres over the entire coating, printing and embossing range.

With OLBRICH embossing and smoothing system concepts, you also benefit from our "Cross Knowledge" from many other industrial sectors, for which we have been producing corresponding machines for decades.

Exemplary embossing/smoothing technologies:

- Embossing of surface structures

- In-register embossing (EIR)

- Hot vinyl embossing lines

- Smoothing of product layers

Making wallcoverings ready for sale

With OLBRICH's know-how, you can be sure of greater efficiency and noticeable time savings every day: Prefabrication of wallcoverings with our product winders makes it easier for you to further process them in subsequent lines - with maximum reliability.

With our systems you can rely on maximum production reliability and first-class results. For example, you can implement high-quality finishing solutions for duplex/simplex wallcoverings, PVC compact or hot embossed wallcoverings or foam wallcoverings.

In the wallcovering winding machine sector, OLBRICH offers market-leading cutting-edge technologies: Today, several hundred winding machines are in use in international companies of the wallcoverings industry worldwide.

Exemplary packaging technologies:

- Rolls with and without core

- Automatic length measurement

- Setting the winding hardness of the wallcovering rolls

Wallcoverings: Drive and control technology

Maximize your production and data security: With drive and control technology from OLBRICH, you can rely on safe processes in the production of wallcoverings. In this way, you receive all services from one experienced source: We supply you with the mechanical drive and suitable switchgear with OLBRICH top technologies for your system. We only use the latest drive and control technology from quality-oriented manufacturers such as Siemens or Bosch-Rexroth.

Your benefit at OLBRICH: You retain full access to your production process. In addition, we have a dedicated contact person for each automation area.

With our own specialists in the electrical sector, we implement innovative and safe solutions for you in the areas of drive and control technology, user interfaces and visualization systems. The well thought-out architecture of our systems also enables you to retrofit functions and aggregates later on. In addition, we also retrofit already existing systems with state-of-the-art technologies.

Exemplary services for drive and control technologies:

- Conception and realization of the drive technology

- Switchgear planning and manufacturing

- Software engineering for CPU

- Visualization systems

- Support and assistance with IQ and OQ

- Service over the entire life cycle

- Retrofittings and Upgrades

Services in a full-service package

We implement your individual project in six carefully coordinated steps: